Hvac nitrogen tank and regulator – In the realm of HVAC systems, nitrogen tanks and regulators play a crucial role in maintaining optimal performance and ensuring the safety and efficiency of these intricate systems. This article delves into the multifaceted applications of HVAC nitrogen tanks and regulators, exploring their functions, safety considerations, and best practices for their use.

Nitrogen, an inert gas, is utilized in HVAC systems for a variety of purposes, including purging, leak detection, and pressurizing. By understanding the different types of nitrogen tanks and regulators available, HVAC technicians can select the most appropriate equipment for their specific needs.

Overview of HVAC Nitrogen Tank and Regulator

Nitrogen tanks and regulators are essential components in HVAC systems. They provide a source of nitrogen gas for purging, leak testing, and pressurizing various system components.

Nitrogen tanks come in different sizes and capacities, typically ranging from small portable cylinders to large stationary tanks. Regulators control the flow of nitrogen from the tank and allow for precise pressure adjustment. The choice of tank and regulator depends on the specific application and the required flow rate and pressure.

Types of Nitrogen Tanks

- Portable Cylinders:Small, lightweight cylinders that are easy to transport and use in confined spaces.

- Stationary Tanks:Larger tanks that are permanently installed and provide a continuous supply of nitrogen.

- Dewar Tanks:Vacuum-insulated tanks that store liquid nitrogen at extremely low temperatures.

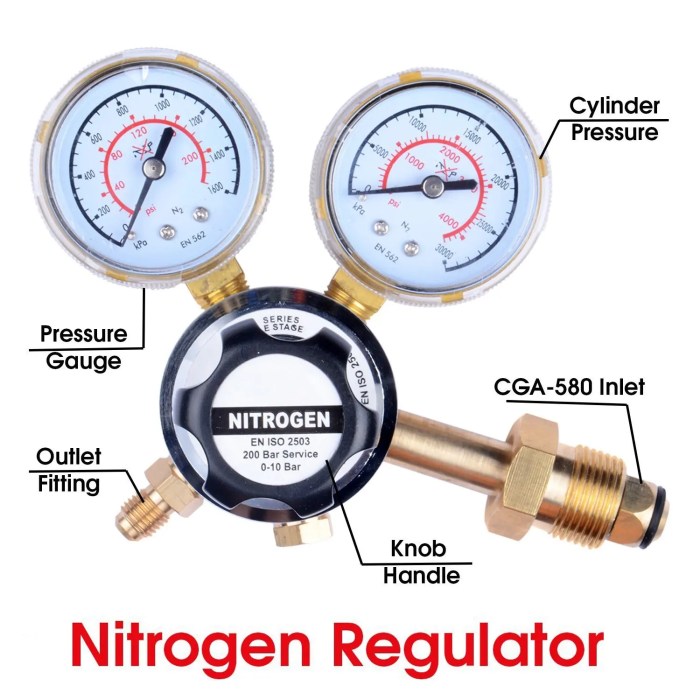

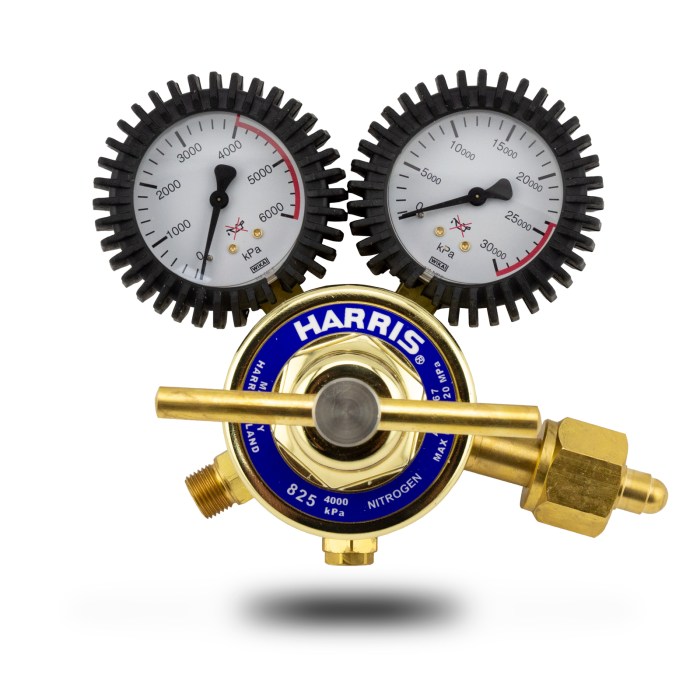

Types of Nitrogen Regulators

- Single-Stage Regulators:Basic regulators that reduce the tank pressure to a single intermediate pressure.

- Two-Stage Regulators:More precise regulators that reduce the tank pressure to two intermediate pressures before delivering the final output pressure.

- Electronic Regulators:Advanced regulators that use electronic control to provide precise and stable pressure regulation.

Applications of Nitrogen in HVAC Systems

Nitrogen finds widespread applications in HVAC systems due to its inert nature, non-flammability, and ability to maintain system integrity. It is employed in various processes, including purging, leak detection, and pressurizing.

Purging with nitrogen involves replacing air or other gases within HVAC components with nitrogen to remove moisture, oxygen, and contaminants. This prevents corrosion, oxidation, and other issues that can compromise system performance and longevity.

Leak Detection

Nitrogen is utilized in leak detection methods due to its ability to create a pressurized environment within HVAC systems. By introducing nitrogen into the system and monitoring pressure changes, technicians can identify leaks and pinpoint their locations efficiently.

Pressurizing

Nitrogen is also used to pressurize HVAC systems during maintenance or repairs. It helps maintain system integrity, prevent air infiltration, and ensure proper operation. For instance, nitrogen pressurization is employed in refrigeration systems to maintain refrigerant levels and prevent leaks.

Specific HVAC components that utilize nitrogen include:

- Refrigeration systems

- Piping systems

- Expansion tanks

- Control valves

Safety Considerations for Using Nitrogen

Nitrogen is a non-toxic, inert gas that is commonly used in HVAC systems. However, it is important to take safety precautions when handling nitrogen, as it can pose certain hazards.

Nitrogen can cause asphyxiation if it displaces oxygen in a confined space. It is important to ensure that there is adequate ventilation when working with nitrogen. Nitrogen can also cause frostbite if it comes into contact with skin. It is important to wear gloves and other protective clothing when handling nitrogen.

Proper Storage and Handling

Nitrogen tanks should be stored in a cool, dry place away from heat sources. Tanks should be secured upright to prevent them from falling over. Nitrogen tanks should not be stored in confined spaces, as this can increase the risk of asphyxiation.

When handling nitrogen tanks, it is important to use a regulator to control the flow of gas. Regulators should be inspected regularly to ensure that they are functioning properly.

Disposal

Nitrogen tanks should be disposed of properly. Tanks should be emptied completely before disposal. Tanks should be disposed of in accordance with local regulations.

Maintenance and Troubleshooting

Nitrogen tanks and regulators require regular maintenance to ensure optimal performance and safety. This maintenance includes inspections, cleaning, and calibration.

Inspections, Hvac nitrogen tank and regulator

Nitrogen tanks and regulators should be inspected regularly for signs of damage or wear. The following are some of the key areas to inspect:

- The tank itself, for any dents, cracks, or corrosion.

- The valve, for any leaks or damage.

- The regulator, for any leaks or damage to the gauges or hoses.

- The hoses, for any cracks or leaks.

Cleaning

Nitrogen tanks and regulators should be cleaned regularly to remove any dirt or debris that could accumulate. The following are some of the steps involved in cleaning these components:

- Turn off the valve on the nitrogen tank.

- Disconnect the regulator from the tank.

- Use a soft cloth or brush to remove any dirt or debris from the tank and regulator.

- Inspect the O-rings on the regulator and replace them if they are damaged.

- Reconnect the regulator to the tank and turn on the valve.

Calibration

Nitrogen regulators should be calibrated regularly to ensure that they are delivering the correct pressure. The following are some of the steps involved in calibrating a nitrogen regulator:

- Connect a pressure gauge to the outlet of the regulator.

- Turn on the valve on the nitrogen tank.

- Adjust the regulator until the pressure gauge reads the desired pressure.

- Turn off the valve on the nitrogen tank.

Common Troubleshooting Issues

The following are some of the common troubleshooting issues that may occur with nitrogen tanks and regulators:

- The nitrogen tank is not delivering any pressure.This could be due to a leak in the tank, regulator, or hoses. It could also be due to a clogged filter or a faulty regulator.

- The nitrogen regulator is not delivering the correct pressure.This could be due to a faulty regulator or a clogged filter.

- The nitrogen tank is leaking.This could be due to a damaged tank, valve, or regulator.

Best Practices for Nitrogen Use in HVAC Systems

Optimizing nitrogen usage in HVAC systems enhances efficiency and cost-effectiveness. Best practices involve minimizing nitrogen consumption while maximizing its benefits.

Tips for Efficient Nitrogen Use

- Leak Detection and Repair:Regularly inspect systems for leaks using a nitrogen leak detector. Promptly repair any identified leaks to prevent nitrogen loss.

- Proper Equipment Selection:Choose equipment designed for nitrogen use, ensuring compatibility and optimal performance.

- Training and Education:Train technicians on proper nitrogen handling, usage, and safety protocols to minimize wastage and ensure safe operation.

Benefits of Using Nitrogen in HVAC Systems

- Improved Efficiency:Nitrogen acts as a dry gas, reducing moisture and condensation within the system, enhancing component performance and reducing energy consumption.

- Corrosion Prevention:Nitrogen displaces oxygen, preventing corrosion of metal components, extending equipment lifespan and reducing maintenance costs.

- Reduced Fire Risk:Nitrogen is non-flammable, eliminating the risk of fire or explosion associated with other gases.

Industry Standards and Regulations: Hvac Nitrogen Tank And Regulator

The use of nitrogen in HVAC systems is subject to various industry standards and regulations. These standards and regulations aim to ensure the safe and efficient use of nitrogen, minimizing risks to personnel and the environment.

Compliance with these standards is essential for businesses and individuals involved in the installation, operation, and maintenance of HVAC systems that utilize nitrogen.

Relevant Standards

- ASHRAE 15:Safety Standard for Refrigeration Systems.

- ANSI/IIAR 2:Standard for Purging Refrigerant Piping Systems.

- NFPA 70:National Electrical Code (NEC).

- OSHA 29 CFR 1910.101:Occupational Safety and Health Administration (OSHA) Standards for Compressed Gas Cylinders and Systems.

Requirements for Compliance

- Proper training and certification for personnel handling nitrogen.

- Use of appropriate equipment, such as pressure regulators, hoses, and fittings.

- Adherence to safety protocols, including proper ventilation and personal protective equipment (PPE).

- Regular inspection and maintenance of nitrogen systems.

- Emergency response plans in case of leaks or accidents.

Guidance on Meeting Standards

To meet these standards, it is recommended to:

- Consult with qualified professionals, such as HVAC technicians or engineers.

- Refer to manufacturer’s instructions and industry best practices.

- Establish clear safety procedures and training programs.

- Maintain proper documentation and records of nitrogen use.

- Stay updated on the latest industry standards and regulations.

Answers to Common Questions

What are the different types of HVAC nitrogen tanks?

HVAC nitrogen tanks come in various sizes and capacities, ranging from small portable tanks to larger stationary tanks. The choice of tank depends on the specific application and the volume of nitrogen required.

How do I safely handle nitrogen tanks?

Nitrogen tanks should always be handled with care. Always wear appropriate personal protective equipment (PPE) and follow the manufacturer’s instructions for storage, handling, and disposal.

What are the common troubleshooting issues with nitrogen regulators?

Common troubleshooting issues with nitrogen regulators include leaks, incorrect pressure readings, and malfunctioning valves. Regular inspection and maintenance can help prevent these issues.